Blog

Decoding the Perfect Watch: Gold Plating vs. Gold PVD Coating

Gold has always been associated with luxury, elegance, and sophistication. In the world of timepieces and jewelry, gold-plated and gold PVD (Physical Vapor Deposition) coated pieces are popular choices for achieving a stunning gold appearance. While we have already explored the basics of these two methods, let’s delve deeper into the topic and examine additional information that will help you make an informed decision. In this article, we will further explore gold plating and gold PVD coating, including their unique benefits, differences, and factors to consider when choosing between the two.

1. What is Gold Plating?

Gold plating involves applying a thin layer of genuine gold onto the surface of another metal, such as stainless steel. This process creates the appearance of real gold at a fraction of the cost, making it an attractive option for those seeking a gold look on a budget. However, it’s important to note that gold plating may not offer the same durability as gold PVD coating and can reveal the base material if scratched.

Advantages of Gold Plating:

- Cost-effectiveness: Gold plating offers a more affordable option compared to purchasing jewelry or timepieces made entirely of solid gold. It allows individuals to enjoy the luxurious appearance of gold at a fraction of the cost.

- Aesthetic Appeal: Gold plating provides a genuine gold look, enhancing the overall aesthetic appeal of the piece. The lustrous and radiant finish adds a touch of elegance and sophistication to jewelry and timepieces.

- Versatility: Gold plating can be applied to various metals, such as stainless steel or brass, allowing for a wide range of design options. This versatility enables the creation of unique and customizable pieces that suit individual preferences.

- Repair and Restoration: Gold-plated jewelry and timepieces can be easily repaired and restored. If the plating wears off or becomes scratched, the item can be re-plated, restoring its original gold appearance.

- Hypoallergenic Properties: Gold plating can provide a hypoallergenic option for individuals with sensitive skin or allergies to certain metals. By plating a non-allergenic base metal with gold, it creates a protective barrier between the skin and the underlying metal, reducing the risk of skin irritation.

- Precious Metal Preservation: Gold plating can be used to preserve and protect precious metals, such as silver or copper. By applying a layer of gold, it prevents the underlying metal from tarnishing, improving its longevity and maintaining its shine.

- Customization: Gold plating allows for customization options, including the ability to combine gold plating with other finishes or colors to create unique and personalized designs.

Disadvantages of Gold Plating:

- Limited Durability: Gold plating is not as durable as other methods of gold application, such as gold PVD coating. The thin layer of gold can wear off over time, especially with frequent use or exposure to harsh chemicals. This can result in a loss of the gold appearance and the exposure of the underlying base metal.

- Prone to Scratches: Gold plating is susceptible to scratches and abrasions. The thin layer of gold can easily be scratched, revealing the base metal beneath. This can detract from the overall appearance and diminish the value of the item.

- Fading and Discoloration: Over time, gold-plated jewelry and timepieces may fade or lose their original color. Factors such as exposure to sunlight, moisture, and certain chemicals can cause the gold plating to tarnish or change in color, leading to a less desirable appearance.

- Limited Thickness: Gold plating typically involves the application of a thin layer of gold, which can range from a few microns to a few micrometers in thickness. This limited thickness can affect the durability and longevity of the gold plating.

- Not Suitable for Allergies: While gold plating can provide a hypoallergenic option for some individuals, it may not be suitable for those with severe metal allergies. If the underlying base metal causes an allergic reaction, the gold plating may not provide adequate protection.

- Replating Required: As the gold plating wears off or becomes damaged, the item may require re-plating to restore its gold appearance. This process can involve additional time and cost, particularly if the item needs to be professionally re-plated.

- Limited Value Retention: Compared to solid gold jewelry or timepieces, gold-plated items generally have lower value retention. The presence of a thin layer of gold over a base metal can affect the resale or appraisal value of the item.

When considering gold plating, it’s important to weigh these disadvantages against the advantages and carefully consider factors such as the intended use, desired longevity, and personal preferences.

2. What is Gold PVD Coating?

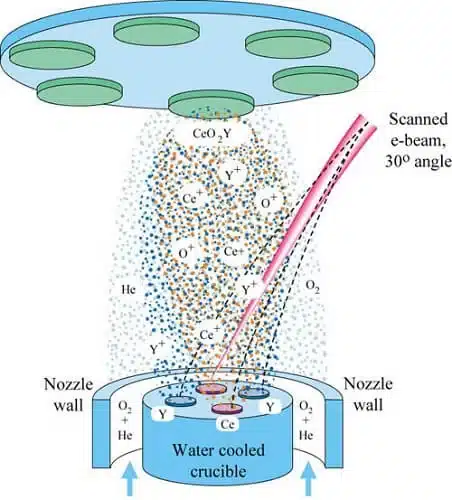

Gold PVD coating is a more expensive process than gold plating, but it is also more durable. PVD stands for Physical Vapor Deposition, and it is a process that involves depositing a thin layer of gold onto a metal surface using a vacuum.

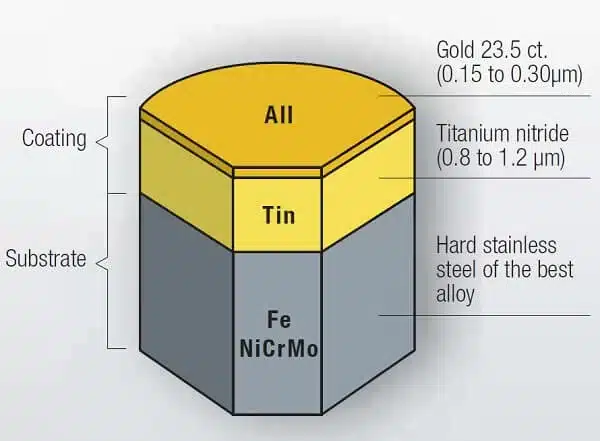

While the gold-colored material used in PVD coatings may not always be genuine gold, some watches and jewelry incorporate a thin layer of genuine 23.5-carat gold within their PVD structure.

In PVD coating, the gold is vaporized and then deposited onto the metal surface in a vacuum. This process creates a very strong bond between the gold and the metal, making it more resistant to scratching and damage.

Advantages of Gold PVD Coating compared to Gold Plating:

- Durability: Gold PVD coatings are highly durable and resistant to wear and corrosion. The titanium nitride used in the PVD process provides a hard and protective layer that enhances the longevity of the coated item. This makes PVD coatings ideal for applications where the item will be subjected to frequent use or exposure to harsh conditions.

- Uniformity: Gold PVD coatings offer excellent uniformity in terms of thickness and color. The coating process ensures an even distribution of the gold particles, resulting in a consistent and uniform appearance across the entire surface of the coated item. This uniformity is particularly desirable for high-end jewelry and luxury goods.

- Versatility: Gold PVD coatings can be applied to a wide range of materials, including metals like stainless steel, titanium, and brass, as well as ceramics and plastics. This versatility allows for greater design flexibility and opens up possibilities for creating gold-colored finishes on various substrates.

Greater Thickness Options: Compared to gold plating, PVD coatings can achieve thicker layers. While gold plating is typically limited to microns in thickness, PVD coatings can range from a few microns to several microns. This increased thickness provides enhanced durability and a more substantial gold-like appearance. - Enhanced Scratch Resistance: Gold PVD coatings offer improved scratch resistance compared to gold plating. The titanium nitride layer in PVD coatings provides a harder surface that can better withstand everyday wear and tear, reducing the likelihood of scratches and preserving the appearance of the coated item.

- Reduced Tarnishing: PVD coatings are highly resistant to tarnishing. Unlike gold-plated items that may require periodic re-plating to maintain their luster, gold PVD coatings retain their color and shine over an extended period. This makes PVD coatings a low-maintenance option that requires minimal upkeep.

- Environmentally Friendly: Gold PVD coating is considered a more environmentally friendly alternative to gold plating. The PVD process is a vacuum-based technique that involves the deposition of a thin layer of gold through vaporization. It produces minimal waste, uses fewer harmful chemicals, and has a lower environmental impact compared to traditional electroplating methods.

3. The Difference between Gold Plating and Gold PVD Coating:

- Process: Gold plating involves directly applying a layer of genuine gold, while gold PVD coating utilizes a vacuum coating process to deposit a gold-colored material onto the surface.

- Material: Gold plating uses real gold, providing a richer appearance. In contrast, gold PVD coatings may utilize gold-colored materials that are not genuine gold, offering versatility in color options.

- Durability: Gold PVD coatings are more resistant to corrosion and wear compared to gold plating, ensuring a longer lifespan and a well-maintained appearance.

Conclusion: When it comes to achieving a gold look in jewelry and timepieces, both gold plating and gold PVD coating offer their unique advantages. Gold plating provides an affordable option with a genuine gold appearance, while gold PVD coatings offer superior durability, corrosion resistance, and color versatility. Understanding the differences and considering factors such as budget and the desired lifespan of the piece will help you make an informed choice. Whether you opt for the cost-effective allure of gold plating or the long-lasting brilliance of gold PVD coating, both methods add a touch of opulence to your jewelry collection, allowing you to shine with timeless elegance.

4. Discover the Superiority of Gold PVD Coating in Exquisite Replica Watches at Beautiful Watch World

At Beautiful Watch World, we take pride in offering exquisite high-end replica watches that are meticulously crafted with the use of advanced Gold PVD Coating technology. Unlike traditional gold plating methods, our timepieces undergo a superior coating process that ensures exceptional color, unparalleled durability, and an impressive high-gloss finish.

Gold PVD Coating is a cutting-edge technique that involves the physical vapor deposition of gold particles onto the surface of the watches under vacuum conditions. This innovative process not only enhances the aesthetic appeal of the watches but also significantly prolongs their lifespan. In fact, our PVD-coated watches boast a lifespan that is 2-3 times longer than their non-coated counterparts, making them a worthwhile investment for watch enthusiasts.

In addition to their enhanced durability, our gold PVD-coated watches exhibit remarkable resistance to scratches, corrosion, and wear. This means that they can withstand the rigors of daily use and maintain their lustrous appearance over time. The Gold PVD Coating technology also allows for precise control over the thickness of the gold layer, ensuring a consistent and uniform coating that adds to the luxurious appeal of our timepieces.

By choosing our gold PVD-coated replica watches, you can enjoy the captivating allure of genuine gold at a fraction of the cost. Each timepiece is meticulously crafted to replicate the finest details of luxury watches, while the Gold PVD Coating adds an extra layer of sophistication and elegance.

Experience the beauty, durability, and brilliance of our Gold PVD-coated watches at Beautiful Watch World. Elevate your style and make a statement with our exceptional collection that combines the allure of gold with the reliability of advanced coating technology.